2. Application scheme

1) Automatic push requirements: The production line automatically collects empty containers, and completes automatic push distribution requirements according to the collection scanner;

2) Collection of distribution goods: freight logistics companies carry out on-time distribution of goods by quantity according to distribution needs;

3) Warehousing of goods in processing plants: automatic retrieval of goods in the warehouse, automatic matching of distribution requirements, and improvement of the efficiency of goods in warehouses;

4) Abnormal alarm in delivery: During the whole process of delivery, when the system detects that the delivery request is overtime and the delivery is abnormal, the system will automatically initiate an alarm prompt;

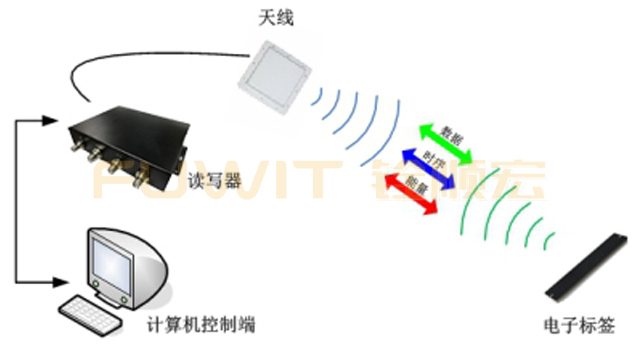

5) Basic principle of data acquisition technology: After the commodity container enters the collection area, the data acquisition device automatically retrieves multiple commodity information according to the collection of RFID electronic tags, and then efficiently carries out commodity in and out of the warehouse, ensuring that the goods are consistent with the distribution needs and improving logistics. delivery efficiency;

6) Efficient and economic benefits: When the goods are in and out of the warehouse, the reading and writing collection equipment can automatically and conveniently identify the goods, and the automatic matching and distribution requirements can improve the efficiency of goods in and out of the warehouse;

7) Real-time: Real-time grasp of the distribution status of all commodities, accurate grasp of inventory status, increase effective inventory, and real-time grasp of warehouse environment conditions and changes;

8) Scalability: Complete cross-regional centralized management, distributed system operation and real-time monitoring system functions, efficiently carry out various business process operations, improve the application of logistics and warehouse management, and improve enterprise efficiency and use value.

3. Solutions

3.1 System Composition

The system is a high-tech product integrating radio frequency automatic retrieval technology, Webservice communication technology, computing control technology, and network technology. The system network topology is shown in the following figure.

4. Application industry

With the gradual improvement of RFID technology, the application is becoming more and more common. RFID front-end development equipment (electronic tags, readers) is closely integrated with the company's core system, which can be widely used in supply chain management and logistics warehouse management industries, and reasonably handle the input/output of supply chain management business process operation data information, business processes The manipulation and tracking of the process can effectively reduce difficulties such as the error rate.

1) Manufacturing stage

The use of RFID technology in the production and processing stage enables automated technology production line operation to realize the identification and tracking of raw materials, parts, semi-finished products and inventory goods in all production lines, reduce labor identification costs and error rates, and improve work efficiency and economic benefits. Especially in the production line that adopts the JIT (Just-in-Time) production process, the raw materials and parts must be delivered to the process on time. After the RFID technology is selected, the raw materials and parts required for the process can be quickly and accurately found from a wide variety of inventory according to the identification rfid tags. RFID technology can also help technicians to immediately transmit stocking information according to the progress of production, complete production line balance, smooth production, and improve the control and tracking of quality.

2) Storage stage

In the warehouse, the most common application of RFID technology is the storage of goods and warehouse inventory, which can be used to complete the actual operations such as automated inventory and pick-up. In all warehouse management, the pickup plan, pickup plan, transportation plan formulated by the supply chain management plan system are closely combined with rfid technology, and various business process practical operations can be efficiently carried out, such as specific accumulation areas, shelves Pickup and stocking, etc. In this way, the accuracy and convenience of the work are improved, the service level is improved, the cost is reduced, the human capital and inventory space are saved, and the misplacement, mistake, theft, damage and inventory of products in the whole logistics warehouse are reduced. , loss caused by incorrect delivery, etc. RFID technology depends on reducing human resources in warehouse inventory. The design scheme of RFID is to automate the filing of products, without manual inspection or scanning of barcodes during collection, which is faster and more accurate, and reduces wear and tear. RFID solutions provide accurate information about inventory levels, allowing technicians to quickly identify and correct diseconomies of scale operating conditions, enabling rapid supply and minimizing storage costs.

3) Shipping stage

In transportation management, RFID tags are attached to goods and vehicles in transit, and RFID receiving and forwarding equipment is installed at some checkpoints on the transportation line. After receiving the RFID tag information, the receiving device and the location information of the receiving place are submitted to the communication satellite, which is then transmitted to the transportation scheduling system by the communication satellite, and sent to the database for query.

4) Shipping/Distributor stage

In the distribution stage, the use of rfid technology can greatly accelerate the speed of distribution, improve the efficiency and accuracy of the whole process of picking and distribution, and reduce labor and distribution costs. If all products arriving at the intermediate distribution management center are affixed with RFID electronic tags, when entering the central distribution management center, the pallet will load the label content on all the boxes on the tray according to a reader. The system checks this information against delivery records for possible inaccuracies, and then upgrades the RFID tag to a new product storage location and condition. This ensures precise inventory control, and even provides accurate information on how many boxes are currently in the middle of a shipment, where the shipment originates and arrives, and its estimated arrival time.

5) Retail stage

RFID can improve retailers' inventory management, realize timely replenishment, effectively track transportation and inventory, improve work efficiency and reduce errors. In addition, intelligent electronic tags can supervise the validity period of some timely products; stores can also use the RFID system to realize automatic scanning and charging at the payment station, thereby replacing manual collection. RFID electronic tags in the sales link of supply chain management terminal equipment, especially in shopping malls, avoid manual intervention in the tracking process, and can be converted into 100% accurate business process data information, so it has great temptation.

For more RFID products and solutions, please visit the company's official website (https://www.fuwit.com.cn/), or online customer service (400-8331-258) for consultation

热品推荐